Advantages

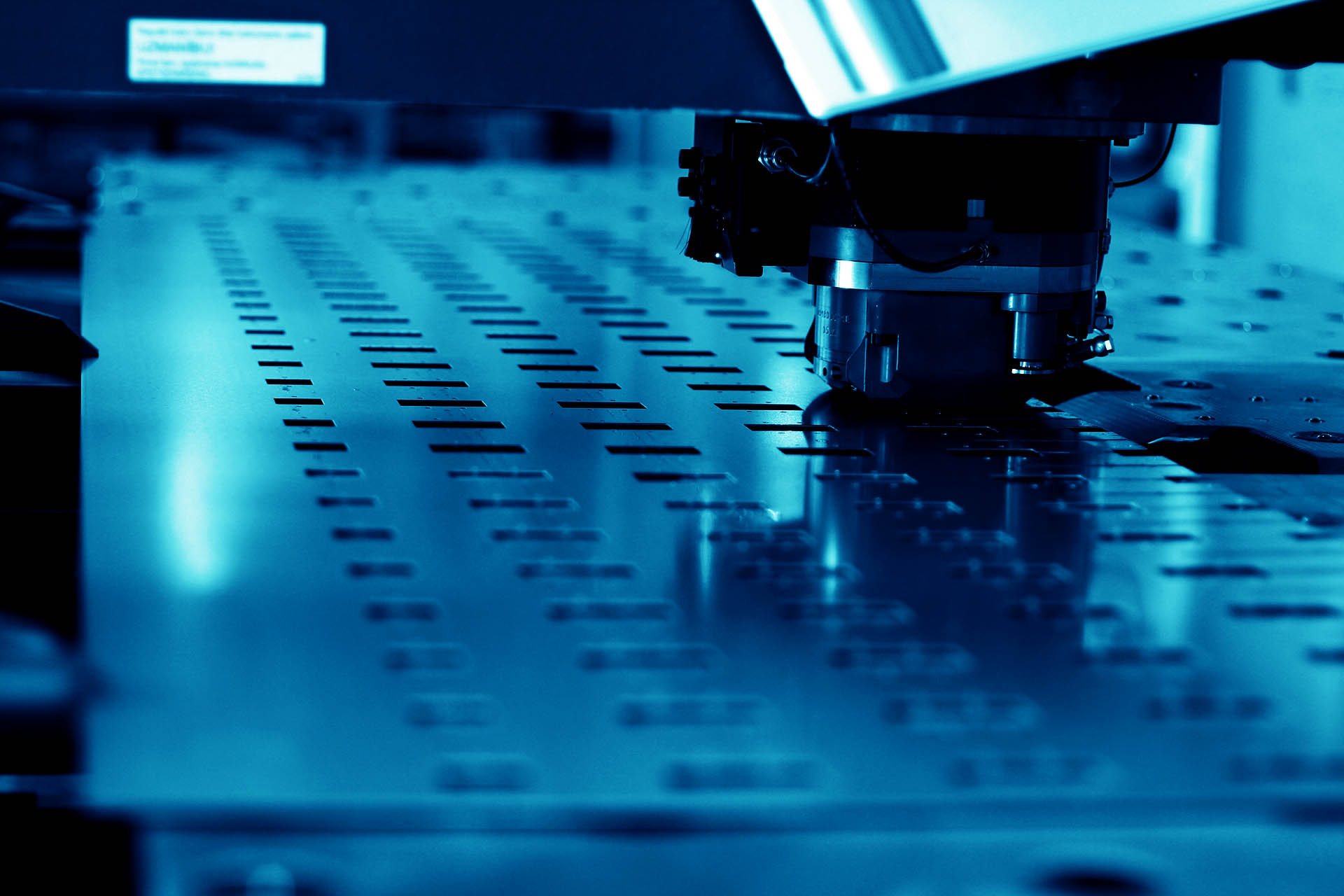

CNC Punching has many distinctive advantages for some operations. This method can be considerably faster and cheaper, or the only choice in some cases where laser cutting will not work. Our CNC Punches perform a variety of multi-step tasks in one function – such as: punching louvers and creating countersinks – eliminating the need for a second operation. These time reducing functions helps reduce labor costs. It is also more economical to use CNC Punching over Laser Cutting when you have parts with numerous holes. When cutting holes the laser must cut the entire circumference of each hole which can add up over time so it makes CNC punching much quicker on a per hole basis.

Some materials aren’t economical or even possible to cut with a laser such as copper, brass, and thicker aluminum. TPI has maintained all of our CNC Punching capabilities to complement our Laser Cutters so we are able to offer our customers the best possible cutting solutions for their jobs.

Materials

- Aluminum

- Brass

- Cold & Hot Rolled Steel

- Copper Bus Bar

- Galvanized Steel

- Stainless Steel

Equipment

-

AMADA EMK-3612-M2

- Capacity – 33 tons

- Thickest Material –.177 mild steel

- Maximum Sheet Size w/o reposition –60 x 120, (60 x 240 w/ one reposition)

- Maximum Hole Diameter – 4 ½”

- Number of Stations – 58 sta. 4A/I (2 x 4½”, 2 x 1¼”)

-

Amada Coma (2)

- Capacity – 55 Tons

- Table Travel – 50″ x 72″

- Thickest Material – 1/4″

- Maximum Sheet Size w/o reposition – 144″ x 50″

- Maximum Hole Diameter in 1/4″ – M.S. 2 3/4″

- Maximum Hole Diameter – 4 1/2″

- Number of Stations – 58 with (2) A/I

-

Amada Pegas 344

- Capacity – 30 tons

- Sheet Size – 40 X 40

- Thickest Material – 1/4 “

- Max Hole Diameter – 4.5″

- Number of Turret Stations – 32 station

- Strokes Per Minute – 350

- Axis Speed – 2000 IPM

- Hits Per Min. 1″ centers – 220

- Control Model – Fanuc 6M

- Drive motors – DC Servo